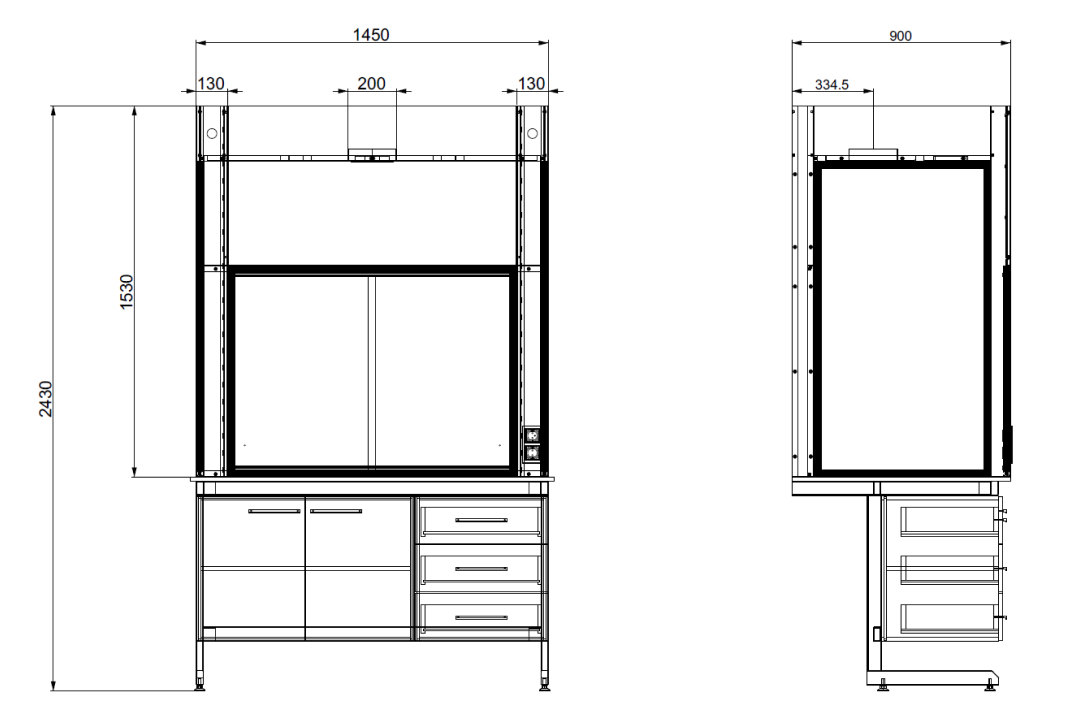

VENTILATED WORK CABINET

Alptek’s Ventilated Work Cabinet establishes a benchmark for safety and functionality within your laboratory environment. Carefully crafted, this work cabinet seamlessly integrates secure storage with effective ventilation, setting a superior standard. Engineered for outstanding performance, it guarantees optimal air quality while offering a specialized area for your essential work tools. Tailor your configuration for accuracy and convenience. With Alptek’s unwavering dedication to quality, rely on our Ventilated Work Cabinet to elevate safety and efficiency in your laboratory procedures.